To precede into being one of the biggest customer-centric companies for our online, offline and overseas customers.

Sejal Exports (India)

CE - 4011, Bharath Diamond Bourse

BKC, Mumbai - 400051

Maharashtra, India

websales@sejalgems.in Open in Google Maps

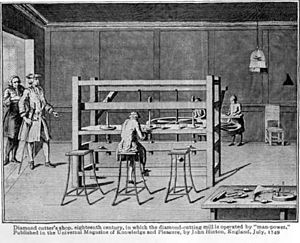

Diamond Cutting Process > Planning

Diamond manufacturers analyze diamond rough from an economic perspective, with two objectives steering decisions made about how a faceted diamond will be cut. The first objective is that of maximum return on investment for the piece of diamond rough. The second is how quickly the finished diamond can be sold. Scanning devices are used to get a 3-dimensional computer model of the rough stone. Also, inclusions are photographed and placed on the 3D model, which is then used to find an optimal way to cut the stone.

Maximizing Value

The process of maximizing the value of finished diamonds, from a rough diamond into a polished gemstone, is both an art and a science. The choice of cut is influenced by many factors. Market factors include the exponential increase in value of diamonds as weight increases, referred to as weight retention, and the popularity of certain shapes amongst consumers. Physical factors include the original shape of the rough stone, and location of the inclusions and flaws to be eliminated.

Weight Retention

The weight retention analysis studies the diamond rough to find the best combination of finished stones as it relates to per caratvalue. For instance, a 2.20 carat (440 mg) octahedron may produce (i) either two half carat (100 mg) diamonds whose combined value may be higher than that of (ii) a 0.80 carat (160 mg) diamond + 0.30 carat (60 mg) diamond that could be cut from the same rough diamond.

The round brilliant cut and square brilliant cuts are preferred when the crystal is an octahedron, as often two stones may be cut from one such crystal. Oddly shaped crystals, such as macles are more likely to be cut in a fancy cut—that is, a cut other than the round brilliant—which the particular crystal shape lends itself to. Even with modern techniques, the cutting and polishing of a diamond crystal always results in a dramatic loss of weight, about 50%. Sometimes the cutters compromise and accept lesser proportions and symmetry in order to avoid inclusions or to preserve the weight. Since the per-carat price of a diamond shifts around key milestones (such as 1.00 carat), many one-carat (200 mg) diamonds are the result of compromising Cut quality for Carat weight.

Color Retention

In colored diamonds, cutting can influence the color grade of the diamond, thereby raising its value. Certain cut shapes are used to intensify the color of the diamond. The radiant cut is an example of this type of cut.

Natural green color diamonds most often have merely a surface coloration caused by natural irradiation, which does not extend through the stone. For this reason green diamonds are cut with significant portions of the original rough diamond's surface (naturals) left on the finished gem. It is these naturals that provide the color to the diamond.

Turnaround Minimization

The other consideration of diamond planning is how quickly a diamond will sell. This consideration is often unique to the type of manufacturer. While a certain cutting plan may yield a better value, a different plan may yield diamonds that will sell sooner, providing an earlier return on the investment.

- Picture & Information Courtesy: GIA / Wikipedia